Kia Motors officially opened its new production facility in Mexico today at a grand opening ceremony attended by over 500 people.

[ads id=”0″ style=”float:left;padding:6px;”]Construction of Kia’s new manufacturing plant, located in Pesquería in the northern Mexican state of Nuevo Léon, began in October 2014. The facility – Kia’s sixth overseas production base – represents an investment by Kia and suppliers of US$3 billion.

The ceremony, which took place in the plant’s new assembly shop, was attended by Mexico’s Secretary of Economy, Ildefonso Guajardo Villareal; the Nuevo Léon State Governor, Jaime Rodríguez Calderón; and the Mayor of Pesqueria, Miguel Ángel Lozano Munguía. The delegation of around 100 visitors from Korea included Hyundai Motor Group Chairman Mong-Koo Chung and Kia Motors Corporation Vice Chairman and CEO Hyoung-Keun Lee.

“The new plant here in Mexico represents the next step in Kia Motors’ ambition to become one of the world’s leading automakers,” said Mong-Koo Chung, Chairman of Hyundai Motor Group, during his speech at the ceremony. “The innovative design and world-class quality possessed by the cars produced at the Kia Motors Mexico plant will be embraced by our valued customers not only here in Mexico but also in export-bound countries of Latin America and North America.”

Kia expands its global production capacity

Kia’s new manufacturing plant will have an annual production capacity of 400,000 units, boosting the Korean brand’s global manufacturing capacity to 3.56 million vehicles. Production began in May 2016, with the Mexico plant providing the company with a new production base for the C-segment Kia Forte (known as ‘Cerato’ in some markets). Beginning of 2017, the plant will produce the all-new fourth generation B-segment Rio, which will have its world premiere on 29 September in Paris at the 2016 Mondial de l’Automobile.

[ads id=”0″ style=”float:left;padding:6px;”]In addition to supplying the local Mexican market, where Kia is targeting a 5% market share by 2020, 80% of the facility’s production is destined for numerous other countries in the region, including the USA and other Latin American markets – where demand for Kia cars is expected to increase. The facility is currently operating on one shift, producing around 100,000 cars per year, and is able to manufacture one car every 53 seconds (68 units per hour). A second and third shift will be added in 2017 to bring annual plant capacity to 300,000 units, and Kia expects the plant to be operating at full capacity of 400,000 units utilizing three shifts by the end of 2018.

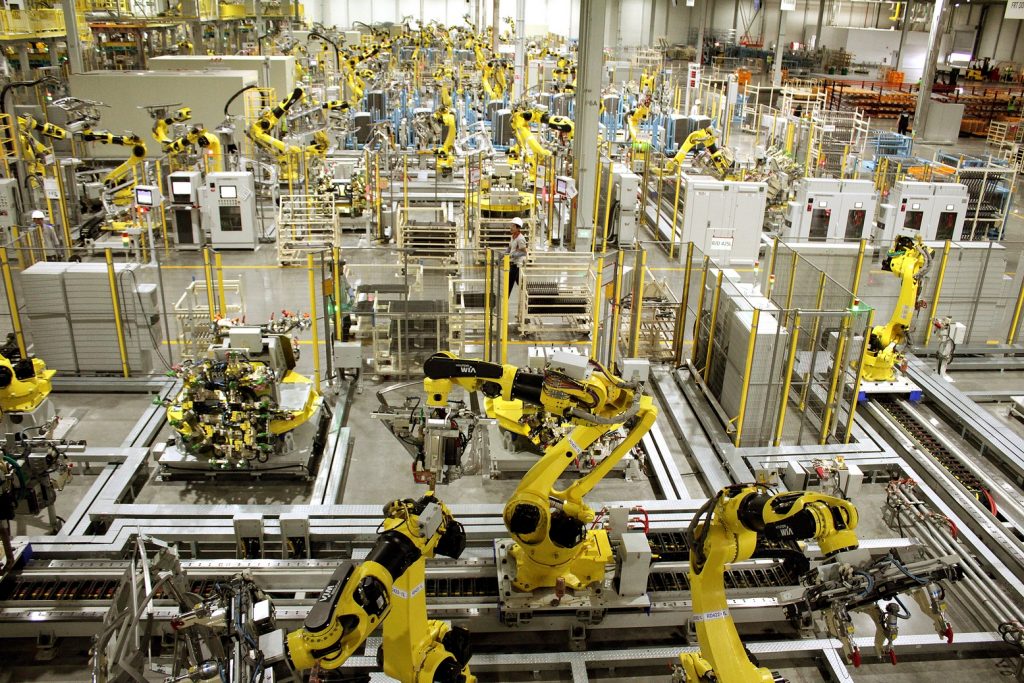

The new plant is a high-tech integrated automotive production facility, with 420 robots automating the press, body and paint shops, as well as the assembly line. Meanwhile, a new quality control center was established to ensure that all vehicles are manufactured to the highest standards. As the final stage in the production process involves advanced component quality assessment and evaluation, quality control is carried out in tandem with Kia’s suppliers, enabling all parties to benefit from any quality-related findings. The quality control center will ensure continuous improvements to vehicle quality as well as the brand’s reputation for producing cars that exceed buyers’ expectations.

14,000 jobs to be created, Kia to fund CSR activities in the region

A significant number of new jobs are being created at the plant. By the end of 2017, approximately 14,000 workers will be employed by the Kia Motors Mexico plant and supplier firms.

The site also includes a training center for assembly line workers. Kia’s systematic approach to vocational training and human resource development will see every employee undergo a 15-day training period before they are assigned to positions on the assembly line, with further opportunities for more advanced training in future.

The Kia Motors Mexico production facility will also invest approximately US$1 million annually in CSR (corporate social responsibility) initiatives for the local citizens of Pesquería. These activities will include the donation of vehicles to public security organizations, support for low-income households and the creation of educational facilities and scholarships.