There are no shortcuts to how to make a good-performing car. I just do my best to find the problem and improve it. This is why Hyundai Motor and Kia are pushing cars in extreme test environments.

California City, west of the Mojave Desert, the most dry land in the western U.S., is the California Proving Ground (Mojave Driving Test Ground) of Hyundai Motor Company and Kia. The outstanding performance and high quality of Hyundai Motor and Kia Electric, which has won brilliant awards at the world’s car awards, is completed here.

Today’s automobiles are a collection of various technologies such as mechanical engineering, electrical, and electronics. In a situation where the elements that make up a car have increased significantly, high quality requires harsh testing beyond the actual road conditions. To discover and solve problems that cannot be found in computer simulations and improve technical perfection.

Hyundai Motor & Kia completed the Mojave Driving Test Center in 2005 in search of extreme conditions. The area is extremely dry with a desert climate. In summer, the average temperature is 39℃ and the ground temperature is over 54℃. On the other hand, in winter, the average warm weather is 26℃, but when there is a storm, it rains heavily. As such, the Mojave Driving Test Site can conduct tests under a variety of conditions.

The Mojave Driving Test Center covers an area of about 17.7 million square meters (about 5.35 million pyeong). It has 12 test paths, including ‘high-speed circuit’, ‘univeral test site’, and ‘long-plate test path’, and if all test paths are extended, the length will reach a whopping 61km. A similar-scale driving test site in the U.S. is so large that only global automakers such as GM, Ford and Toyota have it.

The Mojave Driving Test Center performs local conformity tests, North American legal tests, tests for the enduration, and material environment tests. Lee Seung-yeop, vice president of Hyundai Motor and Kia American Institute of Technology, introduced the Mojave driving test site and explained as follows.

“The tests conducted here can be divided into five main categories. The local suitability test covers product-related sectors such as ride comfort, steering stability, and noise, and the North American law test covers safety-related performance such as vehicle overturn, braking distance, and accident evadance speed. The enduration test measures the condition of the vehicle on various road surfaces, and the material environment test measures the environmental durancy of the parts. We are also focusing on testing the rough road and traction of SUVs that are popular in the North American market.”

At the Mojave Driving Test Center, researchers from all over the world, including Hyundai Motor and Kia’s American Technology Research Institute, are being tested. It tests more than 300 vehicles a year, with an average of 200,000 kilometers across the U.S. only from the test site. The Mojave Driving Test Center is the result of Hyundai Motor’s commitment to providing safe mobility in any environment. It is the driving force behind the increase in sales in North America and around the world, and the basis for the strength that could have been made in the electric vehicle and SUV market.

Determining the heat of electric vehicles in the hot desert

Currently, while the global automobile market is rapidly transitioning to electrification, Hyundai Motor and Kia are being evaluated as the most successful companies in switching to electrification systems. In particular, Hyundai Motor Group’s E-GMP-based dedicated electric vehicle models are well received in markets around the world and are shoisting their unique presence.

Hyundai Motor Group’s E-GMP-based dedicated electric vehicle models boast a high level of perfection.

The background of the high popularity of Hyundai Motors and Kia Electric Vehicles is in the degree of perfection. The requirements for improving the completeness of electric vehicles are different from internal combustion locomotives. Electric vehicles carry a high-density battery and gain more than 300 kg in weight compared to internal combustion locomotives. The key evaluation factor is whether it can withstand the load on the suspension, tires, body, etc. Moreover, managing the heat generated by high-voltage currents and motors that rotate more than 10,000 times per minute is also considered an important evaluation factor.

Hyundai Motor and Kia are actively using the Mojave driving test site to test thermal management performance in extreme environments. On days when temperatures above 45℃ and an irradiance of more than 1,000W per square meter are shown, intensive thermal management and cooling performance tests of electric vehicles are conducted. Lee Seung-yeop, managing director, explained the electric vehicle performance test as follows:

“Electric vehicles are heavier than internal combustion engines. Therefore, driving performance tests such as ride comfort and steering stability are very important. And tests such as charging, discharge, mileage, and heat management, which are unique to electric vehicles, are also being conducted at the Mojave Driving Test Center. This is what has led to the validation of many new technologies related to electrification as the electric vehicle era comes.”

Hyundai Motor and Kia have further increased the intensity of thermal management and cooling performance testing in line with the electric vehicle era. It is to improve the cooling performance and optimize the thermal management system to prevent excessive heat in the motor or battery system even under harsh driving conditions where heavy loads such as trailer towing, climbing, high-speed driving, and winding.

For the Ioniq 5 N, for example, the main goal in the development process was to control the battery temperature not to exceed 60℃, even in harsh driving conditions. After countless repetitions of fast charging and driving at the Mojave Driving Test Site, we were able to meet all the conflicting goals of efficient energy management and maximizing driving performance.

Efforts to improve performance also continue outside the Mojave Driving Test Center. The entire U.S. is the test stage for Hyundai Motor and Kia. Last year, researchers at the Mojave Driving Test Center spent about 10 weeks optimizing battery safety and thermal energy management for electric vehicles in various environments in the United States, including Death Valley, Minnesota, and Oregon.

The performance test of electric vehicles also includes the ‘high-speed cycle’ of course. The high-speed circuit, a 10.3-km-long oval three-lane track, simitated U.S. highways. It is the largest test site at the Mojave Driving Test Site, and can be tested at 200 km/h. As it is large, it takes 3 minutes to run a lap.

The new car undergoes a severe comprehensive endurance test on the high-speed main circuit. It repeats high-speed driving for an average of three months and measures the aging of the vehicle. At the same time, various tests are conducted, such as drive system performance, wind syllable evaluation, etc. It runs 30,000 miles (about 48,000 km) per vehicle, and you have to run more than 4,000 laps to pass the test.

The Mojave Driving Test Center also has a number of road surfaces to evaluate the performance of electric vehicles with batteries on the underside of the vehicle. Considering various external road environmental conditions, it is to evaluate the durability of the lower part of the vehicle on a total of 16 types of road surfaces, including fixed roads, long-roads, and off-road (rough roads).

The endurant test is so harsh that only 10,000 miles (about 16,000 km) will have the same effect as driving 100,000 miles (about 160,000 km) on a regular road. The torsion road surface, in particular, has made the situation that has a big impact on the actual battery and vehicle durability more harsh than it actually is. Hyundai Motor and Kia ensure extreme durability through about 500 driving tests here.

Durability of components that can withstand extreme environments

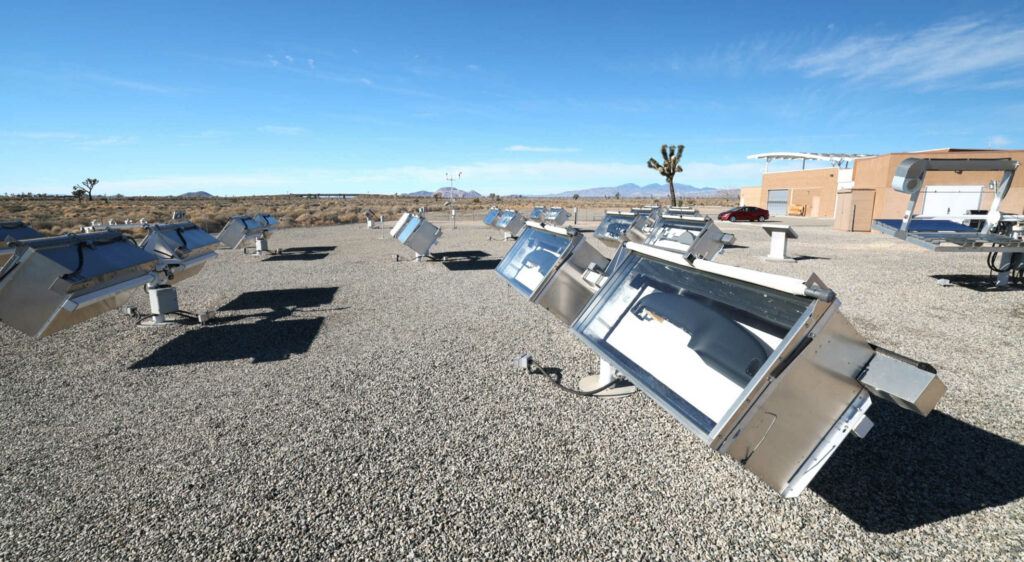

Hyundai Motor and Kia are using the hot weather at the Mojave driving test site to test how each part of the vehicle is affected by the heat. In the ‘Material Environment Sustainability Facility’, the effects of parts on solar and solar heat are measured. It lists numerous parts that make up a car, from bumpers, headlamps, exterior parts such as paint specimens, self-driving sensors, and internal parts such as dashboards and seats. To expose to extreme environments for a long time to see the deterioration of colors and materials.

Yoon Young-jun, an executive researcher of the Durability Test Team at Hyundai Motor & Kia American Institute of Technology, said, “The panels where the parts are displayed move according to the position of the sun and continue to look at the sun head-on during the day. As a result, we can verify durability up to 30 times faster than variant testing in other regions.” It’s about ensuring durability in extreme environments through harsh testing that allows you to soak the equivalent of annual amount of sunlight in just a few months.

A test to make a good running and quiet electric car

The importance of ‘Ride and Handling’ (R&H) in creating a well-run car is great. Researchers at the Mojave Driving Test Center are conducting tests in various sections such as ‘universal test route’, ‘ride reduction and noise test route’, and ‘handling test route’ to evaluate the ride comfort and handling of electric vehicles.

Handling testing helps ensure stable driving performance of vehicles in high, rugged U.S. terrain. With a total length of 5 km, it consists of a rapid curve section and an 8% slope hill, so you can intensively conduct a driving test of the limited situation, such as entering the corner at high speed and exiting at high speed again. This leads to the securing of stable driving performance even on domestic roads with many mountainous terrain.

In the 5.3km-long long plate test with a ramp of 2~12%, the climbing performance test of the driving system is mainly conducted. This is because it is the perfect condition for testing the high torque of electric vehicles. Researchers test the acceleration performance of electric vehicles by repeatedly stopping and departing vehicles at ramps.

Meanwhile, motor-powered electric vehicles have no engine noise, so external noise is more acc. Therefore, Hyundai Motor and Kia are focusing on reducing the noise generated in various road environments and driving conditions as much as possible. The ride and noise test at the Mojave Driving Test Center reproduces the environment of various real roads on U.S. roads. Roads in North America have a variety of paving techniques for each road, so we have applied various paving techniques throughout the entire section to reflect this.

And roads in North America are heavily coated with ‘slurry seals’ that allow asphalt roads to withstand for a long time, given the strong sun’s climate. Therefore, the surface of the road is rough, so there is a lot of residual vibration when driving. There is not a lot of noise in the driving environment, such as roads weathered by wind, rain, sun, etc., impact sounds when driving on broken asphalt roads, railroad crossings, and manhole covers.

Accordingly, Hyundai Motor and Kia will conduct a U.S. local suitability assessment on the test path that reproduces the ‘LA Freeway’, a representative main road, as well as the ride and noise test routes that reproduce 30 various U.S. road conditions such as New York, Detroit, Denver, and San Francisco. It minimizes noise, increases the shock absorption of the vehicle, and also suppresses the vibrations that reach the interior as much as possible to create a good ride.

Mojave driving test site evolving in line with global trends

Another feature of the Mojave Driving Test Center is ‘evoring’. The automotive and market environment demanded by global customers is constantly changing. In line with this, it is to improve and add facilities so that we can conduct more severe testing. Matthew R. R., an American Institute of Technology of Hyundai Motor and Kia, who has been working at the Mojave Driving Test Center for 20 years and is in charge of operation and management.

“With the advancement of technology, we continue to introduce new tests that didn’t exist 20 years ago. It is an important task to build and manage various test rotes and research facilities in line with the environment. The Mojave Driving Test Center is putting in great effort to carry out tests for the future while preserving the desert nature as it is.”

When the Mojave Driving Test Center was completed, there was only one course off-road testing. This is because at the time, the focus was on simulating urban and highway driving in paved test roins. Currently, the off-road course at the Mojave Driving Test Center has been increased to seven courses, and there are additional test trails under construction. To make a car that can respond to any environment in line with the global SUV trend. Kang Hee-jin, a senior researcher at the Vehicle Testing and Development Office of Hyundai Motor and Kia American Technology Research Institute, explained as follows.

“The Mojave Driving Test Center has added a variety of tests since its establishment. In the past, the heat test of internal combustion engines was the main program, but now it has been expanded to various tests such as driving and endurance tests of eco-friendly cars including electric vehicles, and off-road tests of SUVs. The tests are changing as fast as the trends in the automotive industry are changing.”

The U.S. has a lot of opportunities to drive off-road and the environment is diverse. Therefore, it is necessary to verify various conditions in a harsher environment than the road that customers drive to complete strong performance. Lee Kyung-jae, a senior researcher of the chassis energy performance test team at Hyundai Motor Motor and Kia American Institute of Technology, said, “The off-road test is strengthening the verification of various external environmental conditions by adding various road surfaces in addition to the existing unpaved test furnace. We are making powerful SUVs here that can satisfy customers’ needs in line with the global trend of enjoying outdoor activities such as camping.”

The technology that has been honed on the rough leads to everyone’s safety.

The off-road driving test is not just for SUVs. It also leads to securing technology for everyone’s safety. The TCS (Traction Control System) test is a good example.

TCS is an essential off-road feature that allows the vehicle to easily exit the rough road by focusing its driving force on the grounded wheel as it crosses the mound or passes through a pit. Hyundai Motor and Kia have prepared a variety of road surfaces, including sandy roads, gravel roads, and asphalt mounds where TCS can be tested. This is a test stage to boost the performance of the TCS while developing off-road driving performance. Explained by ‘Lance McLaws’, a senior researcher at the chassis thermal energy performance test team at Hyundai Motor & Kia American Institute of Technology.

“I am responsible for the overall off-road driving performance evaluation and tuning, such as driving force control in low-speed rough driving conditions, wheel slip (wheel slip, which means that the wheel slips and occurs when a strong force above the grip is transmitted to the wheel). And we are also conducting driving performance verification on very rough off-road roads. You’ll be surprised to learn how rugged slopes and rocky roads can be in an SUV like the Kia Telluride.”

Off-road testing like this is not just for SUVs. Electric vehicles that deliver power that are immediately close to maximum toque with electric motor operation boast excellent driving performance even on rough roads. Instead, the transmission of force is so fast that it is easy to cause a wheel slip where the wheel slips. To control this, the TCS needs to be refined. Principal researcher Lance McRuss expressed pride in his work, as follows:

”The U.S. Institute of Technology is performing software and hardware tuning, considering a number of aspects, including design and regulation. There are several examples of tuning and enhancing driver safety to make certain obstacles or rough roads more stable. Wheel slip control, which is part of my work, is a safety specification in the end, even though it is an incidental feature. It’s really rewarding to think that one day customers will be able to drive more safely with the features I’ve tuned.”

Matthew Al Shea Mojave Driving Test Center Operations Manager expressed his pride in the Mojave Driving Test Center, saying: “I am always proud that I have been able to experience all the achievements of Hyundai Motor and Kia for the past 20 years. And it’s very rewarding to work with the researchers in charge of vehicle development. Researchers really love cars, and they put all the passion they’ve been trying to make even the smallest changes to the vehicle. This is the Mojave Driving Test Center where you work with people who have a lot of affection and pride in their work.”