Hyundai Motor’s new electric vehicle (EV) factory in Ulsan has achieved a significant milestone, surpassing a 40% completion rate just seven months after construction commenced in November last year. This development is a crucial step in Hyundai’s ambitious plan to expand its EV production capabilities.

Progress Update: Construction Milestones

According to the latest construction status shared by Hyundai Motor, the Ulsan EV factory is making impressive progress. The fair rate of construction, indicating the overall progress, has exceeded 40%. Specific process rates for different sections of the factory are as follows:

• Body: 44.1%

• Paint: 52.1%

• Chair: 46.0%

• Press: 45.5%

This swift progress highlights Hyundai’s commitment to advancing its EV manufacturing capabilities. The factory’s development began with a special agreement between labor and management in July 2022, followed by site construction in October, and a groundbreaking ceremony in November 2023.

Investment and Future Production Plans

The factory, spanning 548,000 square meters, is being constructed on a site previously used as a comprehensive driving test area. Once completed, it will have the capacity to produce 200,000 electric vehicles annually, with plans to scale up to 250,000 units to meet domestic and international market demands.

The factory will first produce the super-large electric sports utility vehicle (SUV) GV90, part of Hyundai’s luxury brand Genesis. Subsequently, various other electric vehicles will be manufactured, making the factory a cornerstone of Hyundai’s EV strategy.

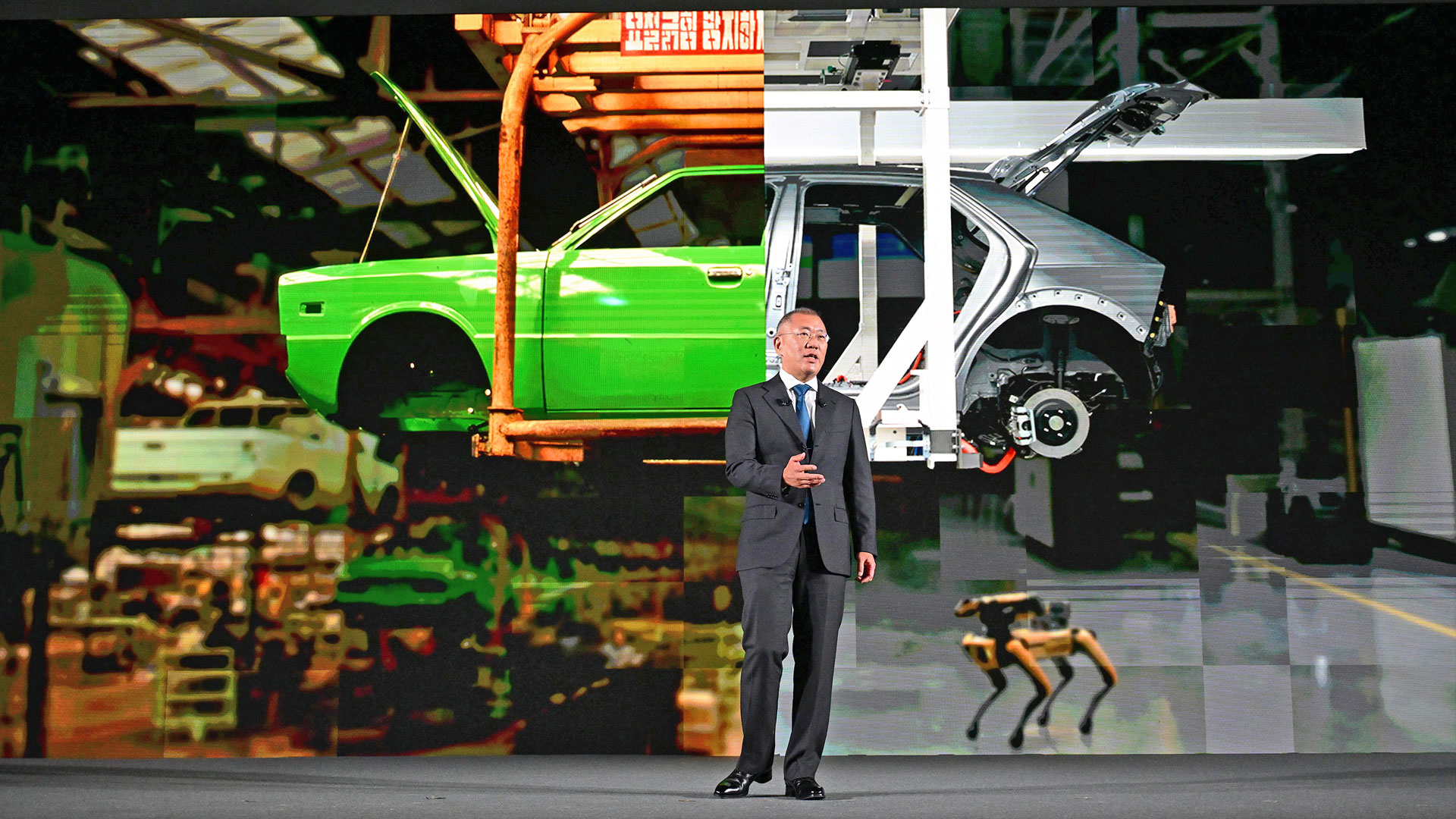

Advanced Manufacturing Innovations

Hyundai Motor is incorporating cutting-edge technologies in the Ulsan EV factory to enhance production efficiency and sustainability. Key innovations include:

• AI-Based Intelligent Control Systems: These systems, developed by the Singapore Global Innovation Center (HMGICS), will optimize manufacturing processes.

• Eco-Friendly Low-Carbon Methods: The factory will adopt sustainable practices to minimize environmental impact.

• Smart Logistics System: Automated component logistics will streamline operations.

• Flexible Production System: This system will allow the factory to adapt to changing market demands and diversify production types.

• Automated Assembly Facilities: Enhancements in automation will improve product quality and productivity.

Commitment to Worker Safety and Comfort

Hyundai Motor is also prioritizing the safety and comfort of its workforce. The factory will feature ancillary facilities designed to provide a comfortable working environment. Safety measures include:

• Typhoon Protection: A 3-meter soil barrier to safeguard against typhoons.

• Earthquake-Resistant Design: Structures designed to withstand earthquakes up to a magnitude of 7.0 on the Richter scale.

Looking Ahead

Considering the current progress, Hyundai Motor is on track to complete the factory by next year, with mass production expected to commence in the first quarter of 2026 after an investment of 3 trillion won (US $2 billion). This project marks the first new car factory built in South Korea in 29 years, underscoring Hyundai’s dedication to leading the EV market.

The Ulsan EV factory is poised to become a pivotal site for Hyundai Motor, driving innovation and setting new standards in electric vehicle manufacturing. With its advanced technologies and sustainable practices, the factory will play a crucial role in Hyundai’s journey towards a greener and more efficient automotive future.

News source: ETNews