Kia Corporation has officially inaugurated the Kia Gwangmyeong EVO Plant, marking Hyundai Motor Group‘s first dedicated electric vehicle (EV) manufacturing facility. Located at Kia Autoland Gwangmyeong in South Korea, the plant signifies a pivotal step in Kia’s journey toward electrification and sustainable mobility.

State-of-the-Art EV Production Facility

The Gwangmyeong EVO Plant boasts an annual production capacity of 150,000 units. Production of the Kia EV3, a compact all-electric SUV, commenced in the first half of this year. The facility is set to begin manufacturing the Kia EV4, a mid-sized electric sedan, in the first half of 2025. Derived from the term ‘Evolution’, the plant embodies Kia’s commitment to innovation and leadership in the future of mobility.

Grand Opening Ceremony

To celebrate the completion of the plant, Kia hosted a ceremony attended by approximately 150 guests. Notable attendees included:

• Jun Young Choi, Executive Vice President and Head of Domestic Production Division at Kia

• Seung Won Park, Mayor of Gwangmyeong City

• O Kyeong Lim and Nam Hee Kim, Members of the 22nd National Assembly of the Republic of Korea

“The completion of the Kia Gwangmyeong EVO Plant solidifies Kia’s first step as an EV leader following the company’s brand relaunch in 2021. With the goal of providing sustainable mobility solutions, we will lead innovation in the EV market and fulfill our responsibilities in helping to deliver a sustainable future,” said Jun Young Choi during his welcoming speech.

Mayor Seung Won Park added, “The completion of the Kia Gwangmyeong EVO Plant will help Gwangmyeong City to establish itself at the center of the EV industry in Korea. Through this, we will strive to promote sustainable development of the local economy and create more jobs.”

Commitment to Sustainability and Innovation

In response to the growing global demand for electric vehicles, Kia has been preparing its global facilities for EV production. The Gwangmyeong EVO Plant represents a significant investment of KRW 401.6 billion over approximately 60,000 square meters. This dedicated EV facility serves as a production hub for Kia’s popular EV models.

The plant is a transformation of Gwangmyeong Plant 2, originally completed in 1987 for the production of small internal combustion engine vehicles like the Kia Pride, Avella, and Stonic. The new facility emphasizes ‘pursuing maximum change through minimal expansion’, considering its urban location and environmental factors such as green space protection.

Advanced Manufacturing and Worker-Friendly Design

The Kia Gwangmyeong EVO Plant incorporates eco-friendly and worker-friendly processes with a full-scale conversion to electrification:

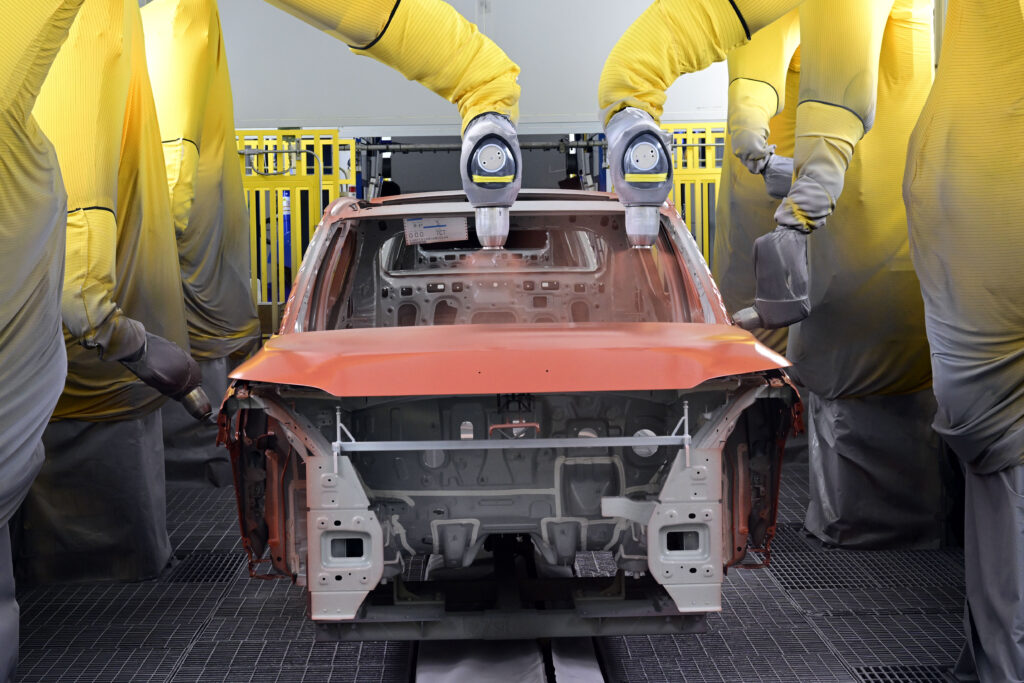

• The body shop features automated guided vehicles (AGVs), transforming it into a high-tech logistics factory.

• The paint shop has enhanced its environmental credentials by adopting a water-based 3C1B method instead of the previous oil-based 3C2B method.

• New equipment has been introduced to improve employee well-being and reduce workload, including machinery that automatically installs high-voltage batteries, wheels, and tires.

Accelerating Kia’s Electrification Strategy

Following the plant’s completion, Kia will ramp up EV production to meet increasing market demand. The Gwangmyeong EVO Plant will serve as a key production base for the company’s EV models, including the EV3 and EV4, with plans to produce 150,000 units annually.

Through the production of high-quality electric vehicles, the Kia Gwangmyeong EVO Plant signifies the beginning of a new era in Kia’s electrification journey, reinforcing its position as a leader in the EV market.