Hyundai Mobis announced the development of a new cooling material designed to prevent battery overheating during ultra-fast charging in electric vehicles (EVs). With this technology, Hyundai Mobis aims to solidify its position as a leader in battery cooling solutions, enhancing competitiveness in the future mobility market.

Introducing the ‘Pulsating Heat Pipe’ Technology

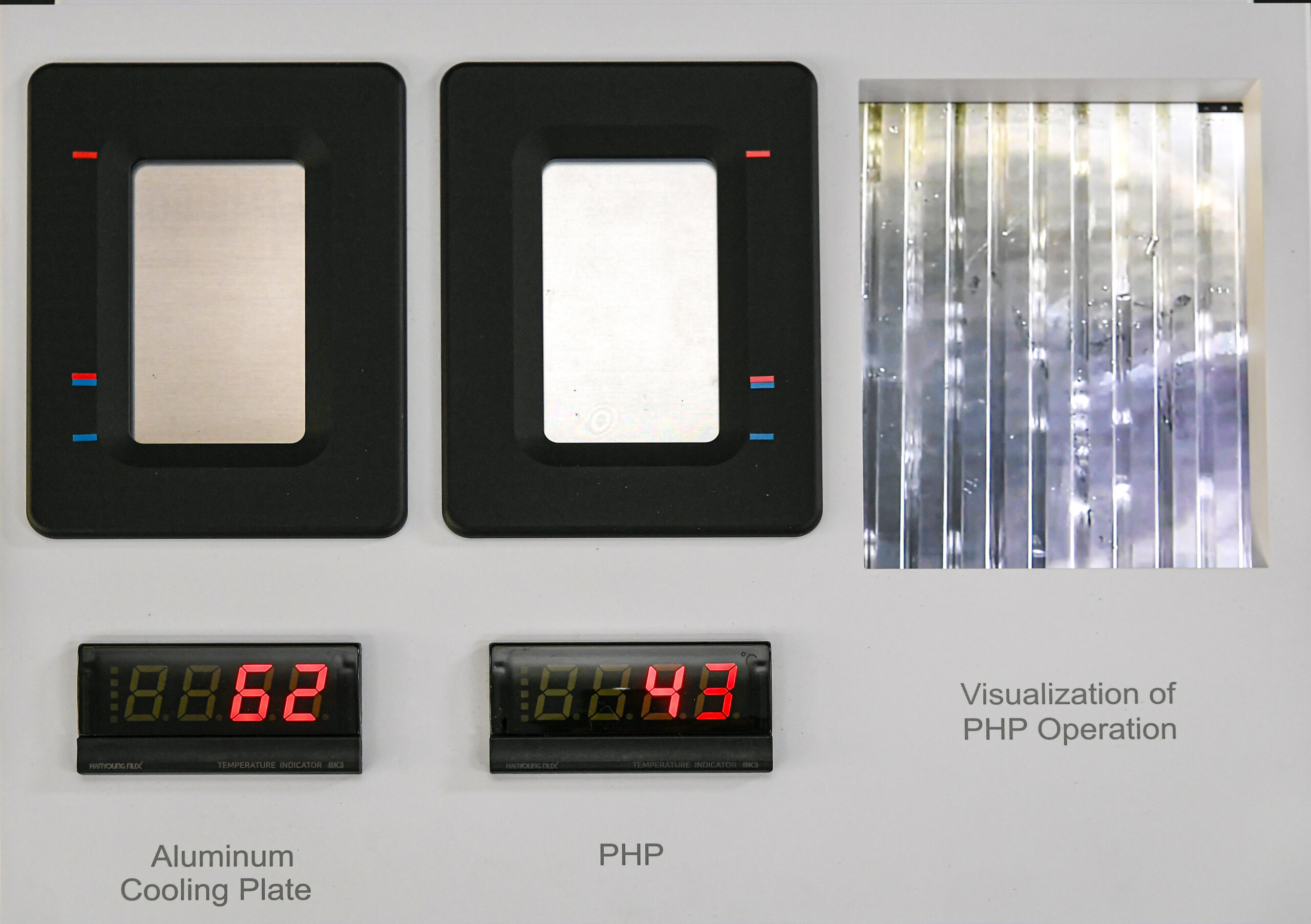

The new material, known as the Pulsating Heat Pipe (PHP), is composed of an aluminum alloy and a refrigerant. Positioned between individual battery cells, PHP effectively reduces the internal temperature that spikes during rapid charging, enabling stable thermal management even under extreme heat conditions. This breakthrough is expected to significantly shorten EV charging times.

How the Pulsating Heat Pipe Works

The heat pipe is a metal conduit that enhances heat transfer efficiency between two objects, widely used in electronic devices like computer CPUs and smartphones for cooling. The pulsating heat pipe, in particular, allows the refrigerant inside to vibrate and circulate, evenly distributing heat. Unlike traditional systems, this technology maintains its performance even in fast-moving vehicles, as it is not affected by gravity.

Compared to standard aluminum, the PHP achieves over 10 times greater heat transfer efficiency, rapidly dissipating heat from overheated battery cells to the outside. Hyundai Mobis is the first company to apply this technology to automotive battery cooling and prepare it for mass production.

Optimized Battery Cooling System

A typical battery system (BSA) consists of multiple battery modules (BMA), a battery management system (BMS), cooling fans, and other electronic components. BMAs, in turn, stack multiple battery cells, requiring optimal cooling structures to prevent overheating.

Hyundai Mobis successfully incorporated the PHP between battery cells to transfer heat quickly to a cooling block, ensuring stable internal temperatures at the module level.

Streamlined Manufacturing and Enhanced Efficiency

To facilitate mass production, Hyundai Mobis adopted a press manufacturing process, simplifying PHP production and reducing costs. The PHP boasts an ultra-thin design of just 0.8mm, a dramatic improvement compared to conventional heat pipes (around 6mm). This innovation achieves a broader surface area for cooling while enhancing the product’s practicality for automotive battery systems.

The company’s efforts to improve the marketability of this solution are expected to accelerate EV adoption globally.

Outlook for High-End Electric Vehicles

A Hyundai Mobis representative stated, “This technology will likely be first adopted in high-end electric vehicles where ultra-fast charging capability is essential.” As battery safety and reduced charging times are critical factors for overcoming the EV market’s growth hurdles, Hyundai Mobis plans to actively promote this technology to global automakers.

Source: Mobis