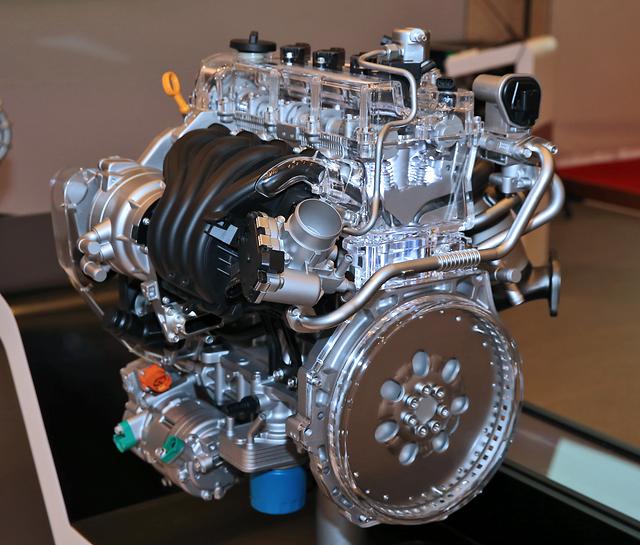

The new Kappa 1.6-liter GDI engine is designed to boost power, performance and fuel economy, while driving down production costs and CO2 emissions in the growing mid-class hybrid electric vehicle (HEV) and plug-in hybrid electric vehicle (PHEV) segments.

The new Kappa 1.6-liter GDI engine is designed to boost power, performance and fuel economy, while driving down production costs and CO2 emissions in the growing mid-class hybrid electric vehicle (HEV) and plug-in hybrid electric vehicle (PHEV) segments.

[ads id=”0″ style=”float:left;padding:9px;”]Arriving in markets early 2016, parallel to the launch of Hyundai & Kia first dedicated hybrid, codenamed as AE (Hyundai’s Prius Rival) and DE (Kia Hybrid SUV) the new unit marks the company’s first combination of the Atkinson cycle, cooled exhaust gas recirculation (EGR) and a long stroke specification to maximize thermal efficiency.

The Atkinson cycle itself reduces the pumping loss through its late intake valve closing time, while enhancing fuel savings by increasing the expansion ratio relatively. In the process, an intake oil control valve (OCV) integrated with the continuous variable valve timing (CVVT) operates to simplify oil flow. Also, the CVVT phasing angle is extended for faster CVVT response.

The EGR system applied to the engine helps to recirculate exhaust gases back into the cylinder and burns them again. The new Kappa HEV engine alone delivers a 3% gain in fuel economy through three stages: gas extracted upstream ensures more than 20% EGR rate, the EGR cooler delivers a cooling efficiency of 98% and the single stage gear EGR valve results in a 56.9 millisecond response time. A specially designed straight intake port increases the tumble flow of the EGR gas to allow fast combustion to further aid economy and boost power output.

Moreover, fuel savings are further boosted by splitting the thermostat cooling temperatures of the cylinder block (105℃) and head (88℃), which then reduces friction and knock by allowing a higher temperature coolant in the block. The cylinder block heats up quickly for lower friction and a more efficient run, while the cylinder head operates at moderately low temperatures to suppress knock tendency, hence improving fuel economy.

The new engine also features a six-hole laser-drilled GDI injector, high pressure fuel supply system of maximum 200 bar, securing clean combustion, improving fuel economy and reducing emissions to fulfill all global emissions standards.

The integration of technologies achieves a new engine thermal efficiency from 30% (of any typical engine) to 40% and secures competitive performance. The new unit produces 105 PS (77.2 kW), 15.0 kgf.m (147 Nm) and will be fit for future hybrid models.