At the end of 2020, Hyundai Motor Company proved its excellence by introducing its dedicated electric vehicle platform ‘E-GMP’, and then improved the existing platform to the next level and further standardized and modularized core electric vehicle parts such as batteries and motors, ‘Integrated Modular Architecture (IMA)’.

It was decided to complete the development system by 2025. The current plan is to standardize batteries and motors that reflect separate specifications for each individual electric vehicle model and apply them flexibly for each vehicle class, thereby promoting efficient EV lineup expansion and strengthening of commercialization.

As a new electric vehicle architecture, Hyundai will introduce an electric vehicle platform ‘eM’ for passenger use and ‘eS’, an electric vehicle platform exclusively for PBV (purpose-based mobility) in 2025. The eM platform is characterized by an expanded common range compared to E-GMP by applying standard modules, and is developed in a form that can be applied to all segments. The drivable range (AER) will be improved by more than 50% compared to the current IONIQ 5, and various new technologies such as level 3 or higher autonomous driving technology and basic OTA update for all models will be installed.

“eS” will be developed with a flexible structure in the form of a skateboard, and will play a role in responding to B2B (business-to-business) demands such as delivery and car hailing.

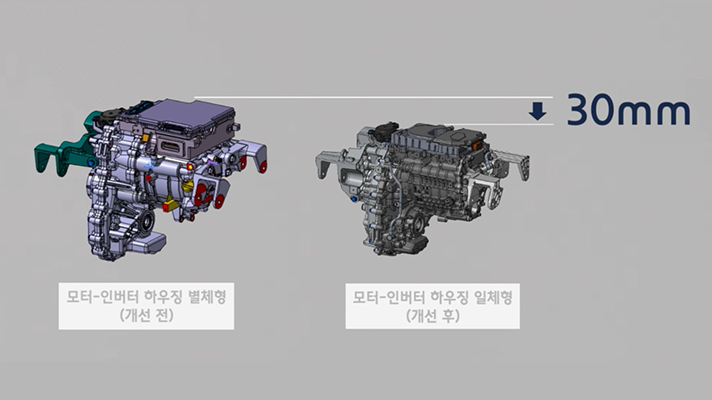

Along with the standardization of batteries and motors, Hyundai Motor Company is also promoting product enhancement through cost reduction and performance improvement of each system. Through this, Hyundai Motor plans to improve battery energy density by 50% compared to 2021 and cut costs by 40% by 2030, and reduce the cost of motors by 35% and weight by 30%.

The battery system is standardized into a total of 9 types, unlike the existing battery packs that are different for each vehicle type. By flexibly applying standardized battery packs, it is expected that it will become easier to respond to demand by vehicle class.

In addition, Hyundai Motor Company has changed the ‘Cell-to-Module’ battery process, which currently consists of a cell-module-pack stage, to a ‘Cell-to-Pack’ method that excludes modules in 2025. It will increase the energy density. Furthermore, the application of the ‘Cell-to-Frame’ process, which integrates the body and the battery by directly attaching the battery cells to the chassis, is also being considered.

The motor system is standardized and developed into a total of five types that can encompass the needs of each model.