Hyundai Motor Group unveiled its groundbreaking 2-stage motor system, which is now available on the high-performance Hyundai IONIQ 6 N. Electric vehicle enthusiasts have long yearned for a car that offers exceptional efficiency during daily driving while simultaneously delivering instant and powerful acceleration.

By balancing power, efficiency, and durability, Hyundai has overcome one of the most complex challenges in EV engineering—creating a motor drive system that excels in both city commutes and high-speed performance driving.

Understanding the Core: How Hyundai’s Motor Drive System Works

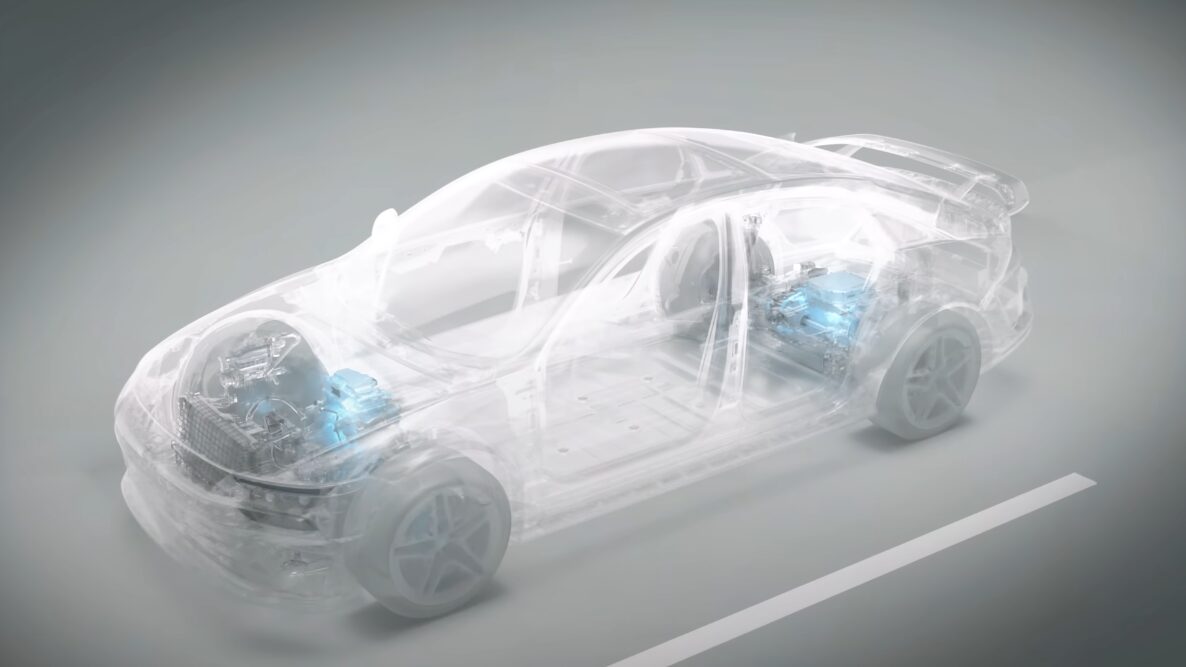

An electric vehicle doesn’t move by its motor alone. The motor drive system is a trio of essential components:

- Motor – Generates torque that drives the vehicle.

- Reducer – Transfers that torque to the wheels.

- Inverter – Acts as the “conductor,” converting DC power from the battery into AC power and controlling how and when it’s delivered.

At the heart of this system is the inverter, which manages electric flow through semiconductor switches. When these switches open and close in carefully timed patterns, the rotating magnetic field generated pushes and pulls the rotor—spinning the motor and propelling the car forward.

Expanding Power Potential: Hyundai’s Next-Generation Inverter

Traditional EVs rely on a 6-switch inverter to manage voltage and current. Increasing output typically means boosting current, which leads to added weight, more heat, and reduced efficiency.

Hyundai solved this by re-engineering the inverter itself. The IONIQ 6 N’s new 12-switch, 2-stage inverter dramatically expands voltage utilization by approximately 70%, delivering higher power output without compromising efficiency.

How It Works

- Stage 1: Under normal conditions, only high-efficiency Silicon Carbide (SiC) switches operate, maximizing energy savings.

- Stage 2: During high-speed or high-power driving, an additional set of silicon switches activates, combining with the SiC set to deliver peak performance.

This dual-stage control allows the inverter to dynamically switch between efficiency and power, depending on real-time driving conditions.

Advanced Control: Precision That Redefines Smooth Power Delivery

Doubling the inverter switches didn’t just add hardware—it required a complete overhaul of the control architecture.

With 12 switches working in unison, the control system must coordinate far more combinations than before—like two perfectly synchronized riders on a tandem bicycle. The result is smoother voltage vector transitions and seamless torque delivery.

Hyundai achieved this with a transfer switch mechanism that intelligently switches between modes:

- High-efficiency mode for daily driving.

- High-power mode for performance and acceleration.

This innovation ensures that the IONIQ 6 N delivers instant, precise response under load while maintaining exceptional driving smoothness at lower speeds.

Compact Power: A Smarter Inverter Design

Despite the added complexity, Hyundai’s engineers avoided the typical trade-offs of size and weight. The solution came through in-house-developed power modules.

By integrating nine modules into three, Hyundai created a simpler, lighter, and more compact inverter with improved double-sided cooling for superior thermal performance. The result is a high-output inverter that remains both efficient and durable—essential for sustained performance in the IONIQ 6 N.

Pioneering the Next Generation of Electric Performance

The Hyundai IONIQ 6 N marks the first showcase of this 2-stage motor drive system, but it’s just the beginning. Hyundai Motor Group plans to extend this technology across future models, setting a new standard for EV efficiency, responsiveness, and performance.

As electric mobility evolves, Hyundai’s innovative approach ensures that drivers don’t have to choose between everyday efficiency and track-ready power. With this breakthrough system, Hyundai is not just redefining how EVs perform—it’s reshaping the future of electric driving.