As part of its 2030 strategy, Hyundai Motor is investing heavily in advanced technologies that will shape the future of mobility. Beyond vehicle design and electrification, Hyundai is pioneering in battery innovation, Software-Defined Vehicles (SDVs), AI-powered systems, robotics, and hydrogen fuel cell technology.

Next-Generation Battery Technology

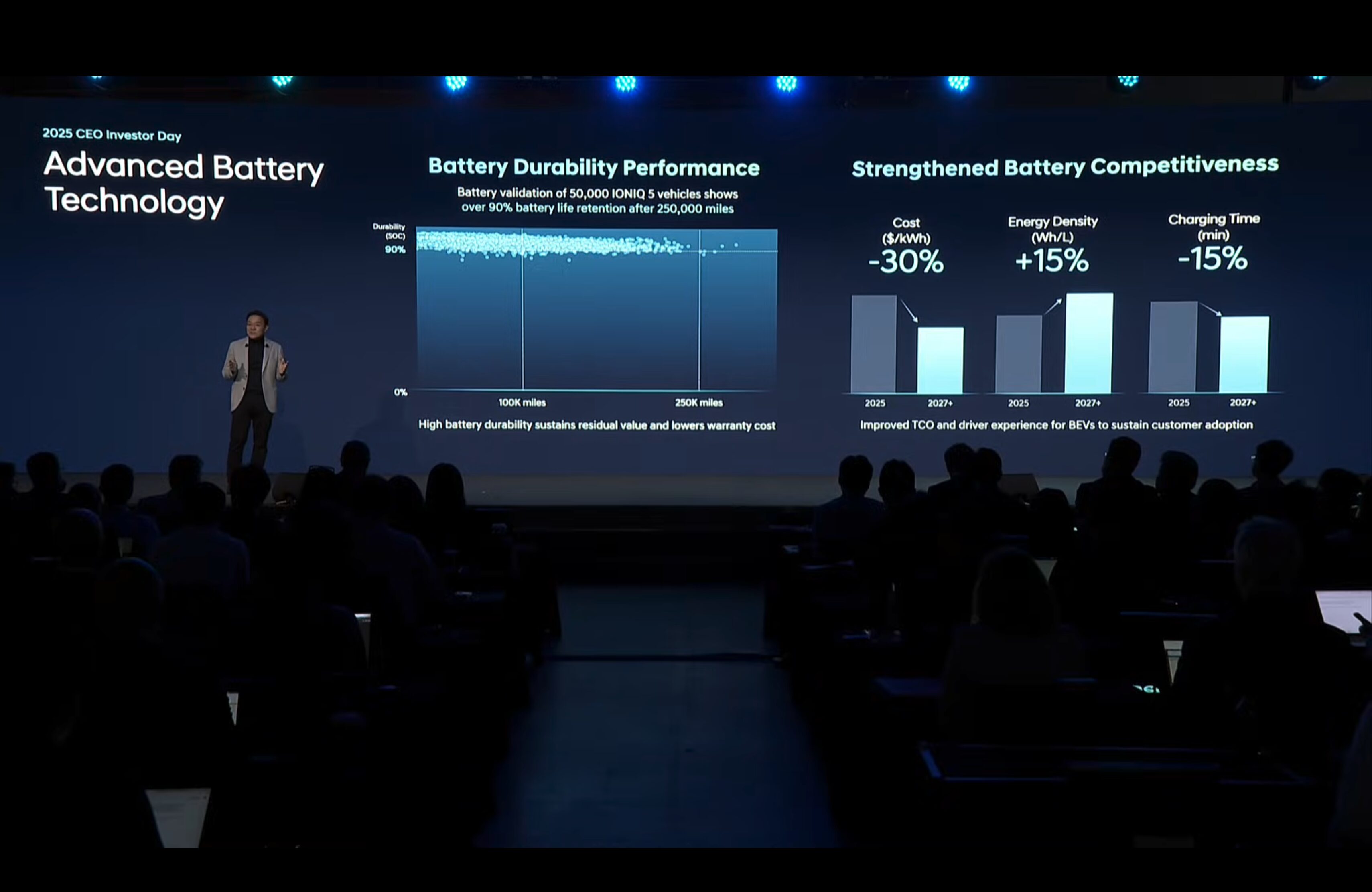

Hyundai’s battery strategy focuses on improving durability, efficiency, and safety while lowering costs. By 2027, Hyundai targets:

- 30% reduction in battery costs.

- 15% higher energy density.

- 15% faster charging times.

The company has analyzed data from over 50,000 IONIQ 5 vehicles, including some that have exceeded 250,000 miles (400,000 km), showing more than 90% battery performance retention — a benchmark in EV reliability.

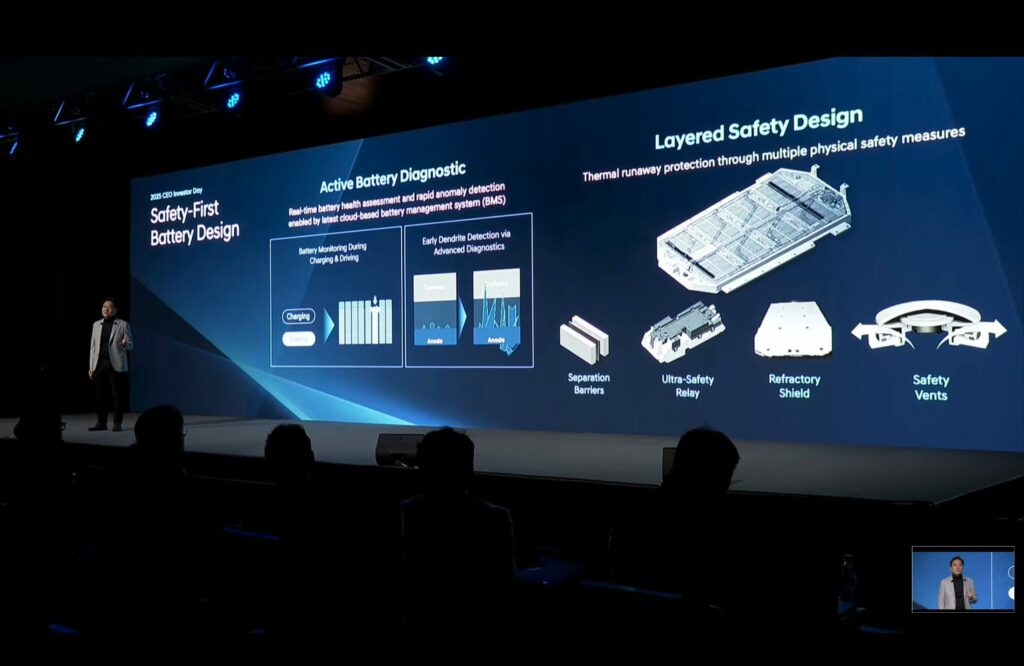

Cloud-Based Battery Management System

From 2026, Hyundai will introduce a cloud-based Battery Management System (BMS) capable of:

- Real-time predictive diagnostics.

- Faster, more precise safety monitoring.

- Multi-layer safety features, including separation barriers, refractory shields, and ultra-safety relays to prevent thermal runaway.

Software-Defined Vehicles (SDV)

Hyundai is transitioning its lineup into Software-Defined Vehicles, where software evolves independently of hardware, enabling continuous upgrades.

Key SDV Innovations:

- CODA Architecture – simplifies vehicle hardware, separating software from hardware for scalability.

- High-Performance Vehicle Computer (HPVC) – central computing power for advanced features.

- Pleos Operating System – a flexible in-vehicle OS supporting over-the-air (OTA) updates, personalization, and enhanced safety.

Coming Soon: Pleos Connect

Launching in 2026, Pleos Connect infotainment will bring:

- Multi-window functionality.

- User profile-based personalization.

- An in-vehicle marketplace for third-party apps, creating new service-based revenue streams.

Artificial Intelligence in Mobility

Hyundai is integrating AI technologies across its ecosystem:

- Atria AI – enables autonomous driving without detailed maps.

- Gleo AI – provides natural, voice-based in-car interaction.

- Capora AI – optimizes fleet management through large-scale data analysis.

Together, these AI systems enhance safety, convenience, and operational efficiency for individual drivers and fleet operators alike.

Robotics and Automation

Hyundai is expanding its robotics footprint through Boston Dynamics integration and next-gen manufacturing.

- Robotics in Factories: Advanced robots support predictive maintenance, digital simulation, and human-robot collaboration.

- Smart Infrastructure: Robotics applied in logistics, mobility services, and urban infrastructure.

- Software-Defined Factories: Hyundai Motor Group Innovation Center Singapore (HMGICS) leads in implementing flexible, AI-driven production systems worldwide.

These innovations improve production efficiency, quality, and adaptability across Hyundai’s global manufacturing network.

Fuel Cell Leadership

Hyundai continues to lead in hydrogen mobility, with 73,000 cumulative fuel cell EV sales to date.

Next-Gen Fuel Cell Systems:

- Designed for commercial vehicles like heavy trucks and buses.

- Improved efficiency, durability, and power output.

- Supporting Hyundai’s vision of a zero-emission logistics ecosystem.