Boston Dynamics unveils the production version of Atlas at CES 2026. Hyundai Motor Group plans deployment at HMGMA by 2028, advancing safe, human-robot collaboration in manufacturing.

Atlas: The Future of Human-Robot Collaboration Begins

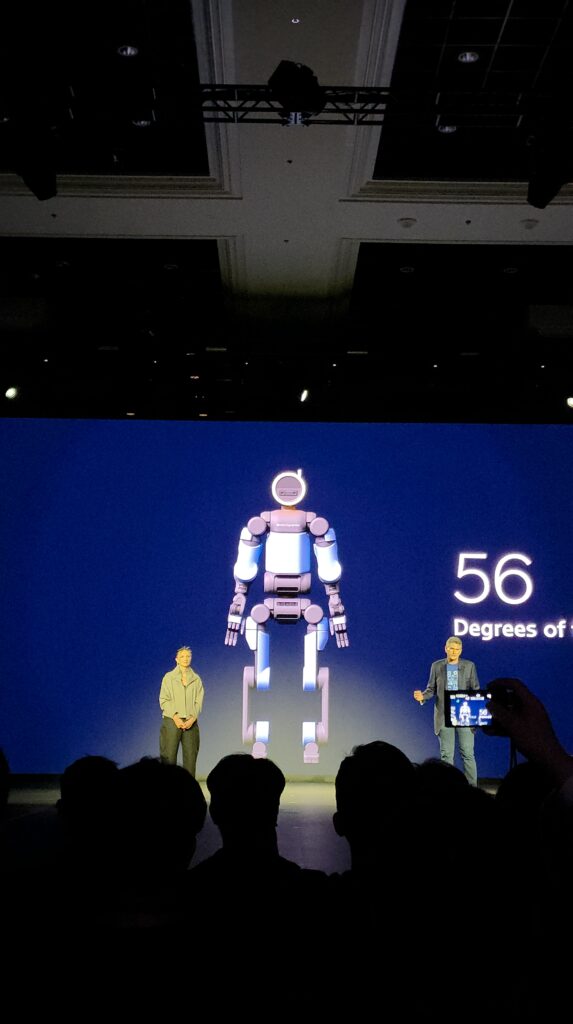

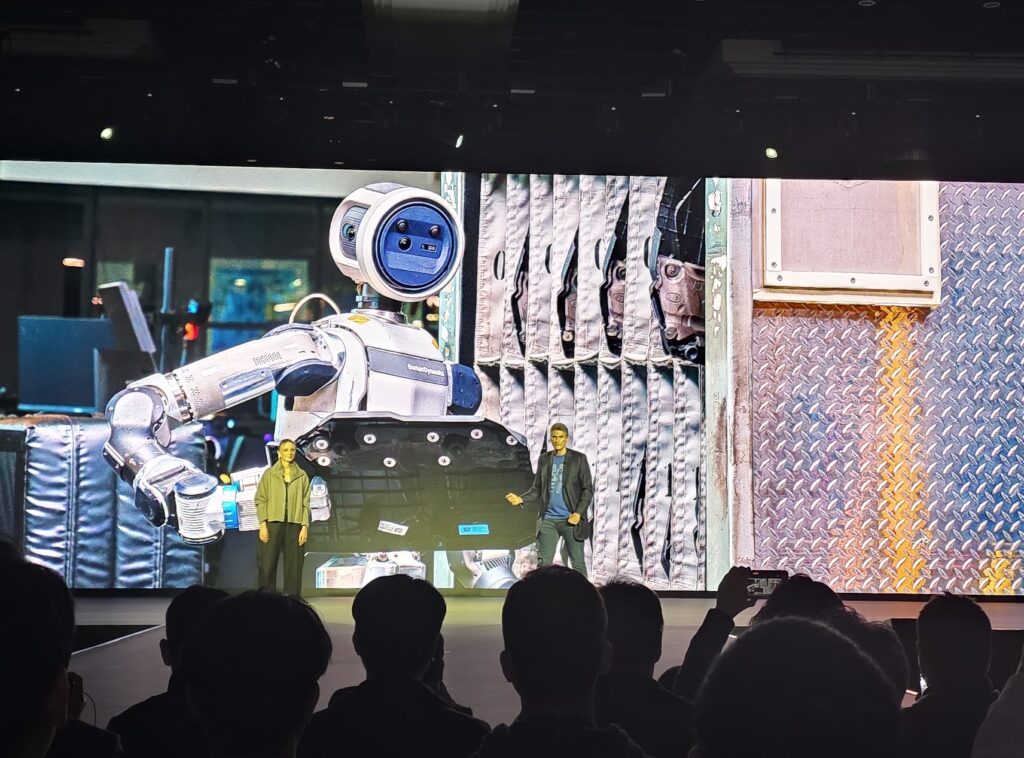

At CES 2026, Boston Dynamics unveiled the product version of its new Atlas® humanoid robot, marking a pivotal moment in industrial robotics. Designed for real-world manufacturing environments, Atlas represents the next step in human-centered AI Robotics, where robots and people work together safely, efficiently, and productively.

Hyundai Motor Group plans to deploy Atlas at Hyundai Motor Group Metaplant America (HMGMA) starting in 2028, beginning with parts sequencing and expanding to more complex assembly tasks by 2030.

Why Atlas Is a Breakthrough in Industrial Robotics

Atlas is a general-purpose humanoid robot built to operate in spaces designed for humans. Unlike traditional industrial robots, Atlas integrates seamlessly into existing facilities without requiring costly infrastructure changes.

Key capabilities include:

- 56 degrees of freedom (DoF) with fully rotational joints

- Human-scale hands with tactile sensing

- Ability to lift up to 110 lbs (50 kg)

- Autonomous operation, including automatic battery replacement

- Water-resistant, durable design for harsh industrial environments

- Full operational range from -4°F to 104°F (-20°C to 40°C)

Most tasks can be taught to Atlas in under one day, significantly reducing deployment time.

Reducing Physical Burden, Enhancing Safety

Hyundai Motor Group’s vision for Atlas centers on human-centered automation. Atlas is designed to take on:

- Repetitive motions

- Heavy lifting

- High-risk or hazardous tasks

- Physically exhausting manual labor

By offloading these tasks to robots, factory workers experience reduced fatigue, fewer injuries, and safer working conditions—while maintaining full oversight and control.

A Phased Deployment Strategy

Atlas will be introduced gradually through process-by-process validation:

- 2028: Parts sequencing at HMGMA

- 2030: Component assembly and machine tending

- Beyond 2030: Repetitive, heavy-load, and complex operations across entire production sites

This measured rollout ensures safety, quality, and reliability at every stage.

Building Toward Robot Commercialization

Atlas is not just a factory robot—it is the foundation for large-scale humanoid commercialization. Hyundai Motor Group expects humanoids to become the largest segment of the Physical AI market, and Atlas will be mass-produced and deployed globally across industrial sites.

By integrating Atlas into its manufacturing ecosystem, the Group is creating real-world training data that accelerates learning, improves performance, and enables scalable adoption across industries such as logistics, construction, energy, and facility management.

Humans Remain at the Center

In Hyundai Motor Group’s factories, people are not replaced—they are empowered. Workers will:

- Train robots

- Supervise operations

- Focus on decision-making and optimization

This collaborative model ensures technology advances with people, not instead of them, setting a new global standard for smart factories.